The 2-Minute Rule for Roar Solutions

Wiki Article

Roar Solutions Fundamentals Explained

Table of ContentsUnknown Facts About Roar SolutionsAn Unbiased View of Roar SolutionsAll about Roar SolutionsGetting My Roar Solutions To Work

The devices register is a detailed database of tools records that consists of a minimum collection of fields to identify each product's location, technical specifications, Ex lover classification, age, and ecological data. This info is important for monitoring and handling the equipment successfully within dangerous locations. On the other hand, for routine or RBI sampling inspections, the quality will certainly be a combination of In-depth and Close evaluations. The ratio of Thorough to Shut evaluations will certainly be determined by the Devices Threat, which is assessed based upon ignition risk (the possibility of a resource of ignition versus the chance of a flammable atmosphere )and the harmful location category( Zone 0, 1, or 2). This variation will additionally affect the resourcing demands for work prep work. Once Lots are defined, you can establish sampling plans based on the sample size of each Whole lot, which describes the number of random devices products to be evaluated. To establish the needed sample dimension, two aspects need to be evaluated: the size of the Lot and the classification of examination, which shows the degree of initiative that should be applied( decreased, regular, or boosted )to the inspection of the Lot. By combining the group of inspection with the Whole lot dimension, you can then establish the proper rejection standards for an example, implying the allowable variety of defective items located within that example. For more information on this process, please refer to the Energy Institute Standards. The IEC 60079 conventional suggests that the maximum period in between evaluations should not go beyond 3 years. EEHA examinations will likewise be conducted outside of RBI campaigns as part of scheduled upkeep and devices overhauls or repairs. These evaluations can be credited toward the RBI example dimensions within the affected Whole lots. EEHA inspections are performed to identify mistakes in electric tools. A weighted racking up system is necessary, as a single piece of equipment may have numerous faults, each with varying degrees of ignition danger. If the combined score of both inspections is much less than twice the mistake rating, the Great deal is deemed appropriate. If the Lot is still taken into consideration undesirable, it must go through a full examination or validation, which may activate more stringent examination protocols. Accepted Lot: The reasons of any faults are recognized. If a common failing setting is discovered, additional equipment may need evaluation and fixing. Faults are categorized by severity( Security, Integrity, Housekeeping ), making certain that immediate problems are examined and addressed quickly to mitigate any influence on safety and security or procedures. The EEHA data source ought to track and record the lifecycle of mistakes along with the rehabilitative actions taken. Executing a durable Risk-Based Examination( RBI )strategy is crucial for making certain conformity and security in taking care of Electric Equipment in Hazardous Areas( EEHA). Automated Fault Scoring and Lifecycle Administration: Easily manage mistakes and track their lifecycle to boost evaluation precision. The intro of this support for risk-based evaluation better strengthens Inspectivity's setting as a best-in-class remedy for governing compliance, in addition to for any kind of asset-centric inspection use situation. If you want finding out more, we invite you to request a presentation and find just how our remedy can change your EEHA management processes.

With over ten years of mixed Ex experience (IECEx/ATEX, EEHA), Saipex started to promote the importance of proficiency of all employees involved in the Hazardous Area field in 2019. In 2021, our partnership with IndEx and Technology Ability International (TSI) marked a landmark in the Saipex roadway to proceed Ex-spouse renovation.

How Roar Solutions can Save You Time, Stress, and Money.

In terms of eruptive risk, a hazardous area is a setting in which an explosive atmosphere is present (or may be expected to be present) in quantities that require unique safety measures for the construction, setup and usage of tools. In this post we check out the challenges faced in the work environment, the threat control procedures, and the called for competencies to work safely.(https://allmyfaves.com/roarsolutions?tab=ROAR%20Solutions)

It issues of contemporary life that we make, save or deal with an array of gases or liquids that are considered combustible, and a series of dusts that are deemed flammable. hazardous area electrical course. These substances can, in certain problems, form eruptive environments and these can have significant and unfortunate consequences. A lot of us know with the fire triangular remove any among the three elements and the fire can not occur, yet what does this mean in the context of dangerous areas? When damaging this down into its simplest terms it is essentially: a mix of a certain amount of launch or leakage of a specific compound or material, blending with ambient oxygen, and the presence of a source of ignition.

This is after that verified via evaluation and screening and is maintained throughout the life of the setup by using the appropriate upkeep techniques, supplemented by regular evaluation. When all these measures are taken, they ought to also be documented. The confirmation dossier includes details such as the hazardous location classification drawing, manufacturers' documents, devices accreditation, design illustrations and computations, examination records, and documents of a person's proficiency and proceeding specialist advancement (CPD), such as via ECA's eCOMS software program.

The Roar Solutions Statements

It is imperative that trainees recognize and have a thorough understanding regarding just what constitutes a harmful location. The pupil must also know why training is necessary before trying to take on work or specifying devices right into a dangerous area. link These locations are also referred to as classified places and are defined as areas which have a high probability of an explosion as a result of the feasible presence of flammable gases, vapors, dusts and so on.

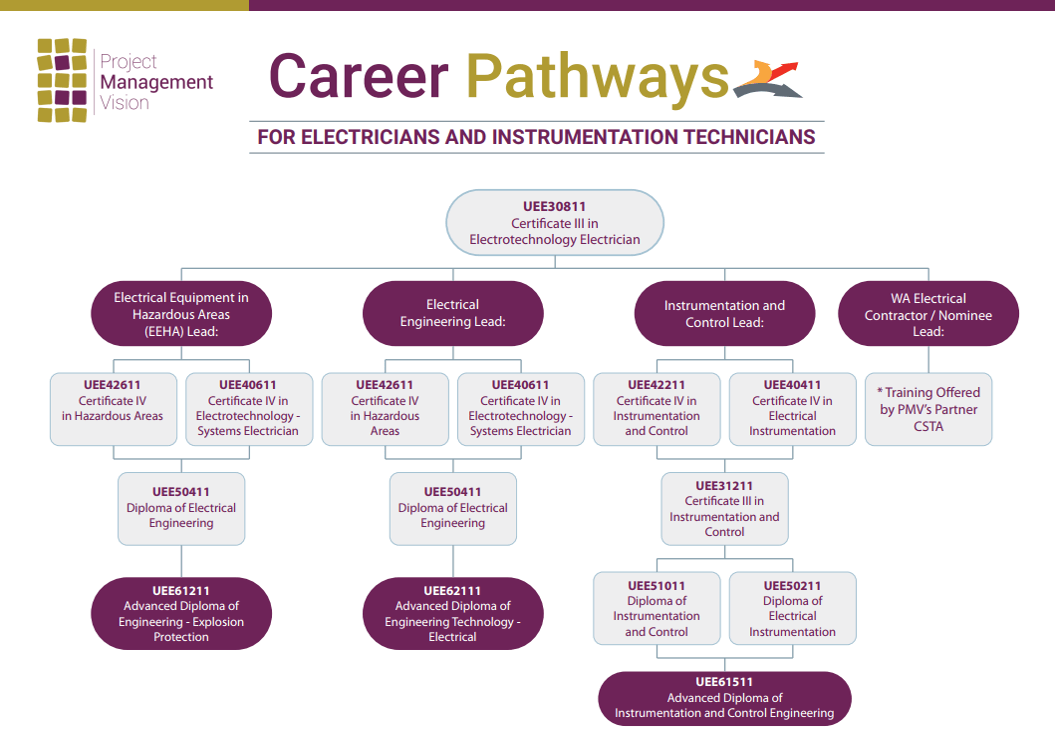

Industries that include harmful locations are currently requiring that electrical employees that are defining or functioning in these locations must have a hazardous area certification that deems them experienced. Jobs in these sectors are really rewarding so you need to be prepared. To fulfill this need for the market, across the country acknowledged training in Certificate IV in Hazardous location Electric and EEHA training on the advancement of proficient experts.

The Best Guide To Roar Solutions

Tech Abilities Australia is a Registered Training Organization providing you with one of the most economical and quickest way in obtaining your credentials - hazardous area electrical course. Our trainers are industry qualified and have numerous years of process experience. Our programs have aided numerous people from company supervisors to daily staff members in acquiring a strong hang on this not so complicated but high danger training

The training likewise includes determining the harmful locations, sources of explosion and the buildings of dangerous products in addition to the responsibilities and features of all parties, policies, systems, standards and technique codes connected to hazardous locations. We supply instrumentation and unsafe area solutions that are in compliance to newest AS/NZS and international industry standards.

Report this wiki page